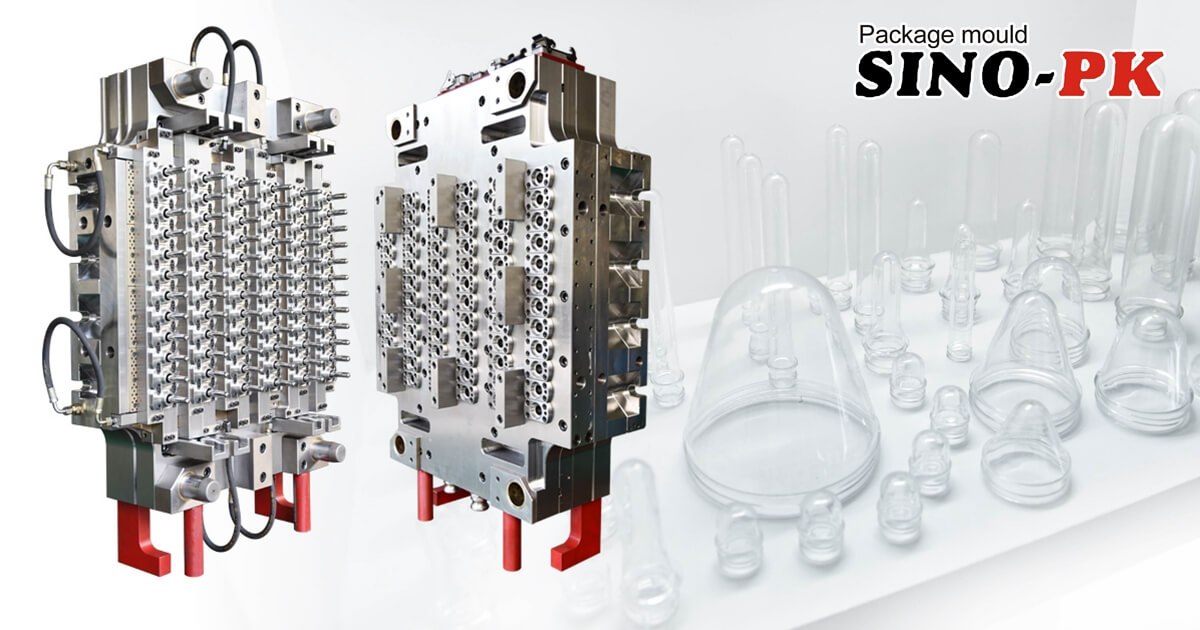

The application of this system does not affect the longevity of the PET mould throughout its useful life Pin-valve System It is possible to make a difference in preform’s wall thickness of less than 0.006 mm by utilizing the Off-Center Correction Technique. Correction Technique for Core Off-Centered Each particular water channel was specially processed to minimize the chance of jamming. Our Preform mould features as follows: Cooling Channel set-upĪn especially designed set-up of water cooling channels combined with special finishing reduced the overall cycle time. It is important to design a preform mould so that the most appropriate steel and processes will be utilized to make it economically feasible for the manufacturer to manufacture the PET preforms. Typically, to fulfill the requirements for designing a PET preform Mould for production, a preform mold must have functional strength, possess sales appeal, be competitively priced, and fulfill practical characteristics. High price: Pneumatically-driven valve, shut off nozzle.The nozzle pin is connected to the hydraulic cylinder (Japanese or European Origin) and designed to be synchronized with the PET preform mould plates movement.Innovative water hoses have been developed to reduce the leaking and reduce water spots on the preforms.Patented correcting technique allows for better control of thickness and reduces possible the preform thickness disorder that might occur during preform injection molding.Its excellent hardness, superior polish, anti-rust and accuracy make it an excellent choice for PET preform moulds making.

“Steven is a very detail-oriented project manager and engineer who can solve problems creatively and also provides excellent service.

0 kommentar(er)

0 kommentar(er)